MAIN FEATURES:

The seat material of general purpose ball valve employs generally non-material,such as PTFE.Limited by the seat material ,the general purpose ball valve can not be used in case of high articles,and ash dregs neither.

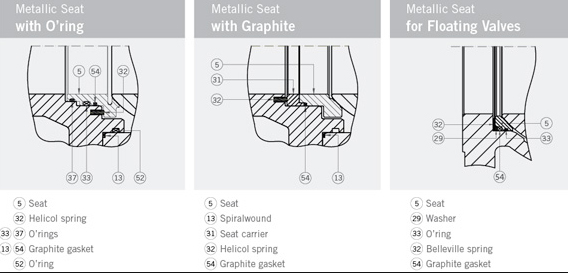

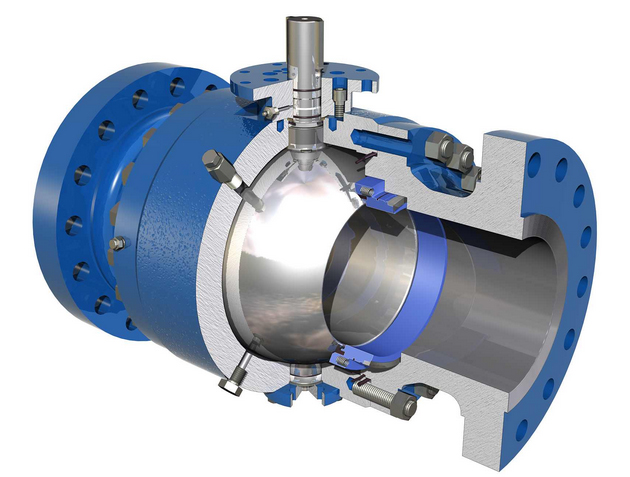

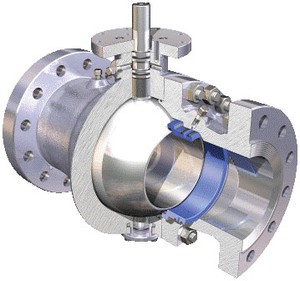

Metal to metal seat design has been employed perfectly for the ball and seat,which has also adopted the advanced hardening technologies,such as ultro-sonic spray coating,nickel base spay welding,surface specially hardening,stellite spay welding,ceramic material with high strength and hardness,and so on.Surface hardness of ball and seat may generally reach more than HRC60, maximun is up to HRC74.

And application temperature of the material may be to 540℃,maximun is 980℃.Combining strength of the material gets to be more than 10000 PSI.Besides,the surface materials posses also very good resistance properties of friction and impact.

Nipo metal to metal seat ball valves are suitable for use in most hard working conditions.

Main Parameter Specification

Design and Manufacture:API 6D,ASME B16.34(BS5351),API 608,MSS-SP-72

Face to Face Dimension:ASME B16.10,API 6D

Flange Connection Dimension:ASME B 16.5

BW Connection Dimension:ASME B16.25

Test and Inspection:API 598,API 6D

Fire-Safe Design:API 607/6FA

Anti-Static Design&Anti Blow-Out Stem

Product Range

Body material: carbon steel, stainless steel, alloy steel

Full bore and reduced bore design

Nominal diameter:1/2″~48″(DN15~DN1200)

End Connection: RF,RTJ, BW

Pressure range: Class150~2500(PN16~PN420)

Working temperature: -46℃~+540℃

Operation : Handle, Gear, Electric actuator, etc

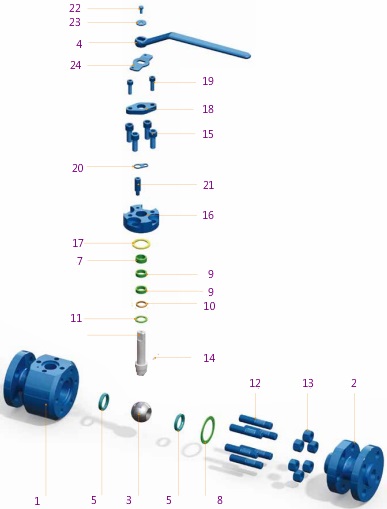

Material List of Cast Steel Trunnion Ball Valves

Material List of Cast Steel Trunnion Ball Valves

.jpg)

.jpg)