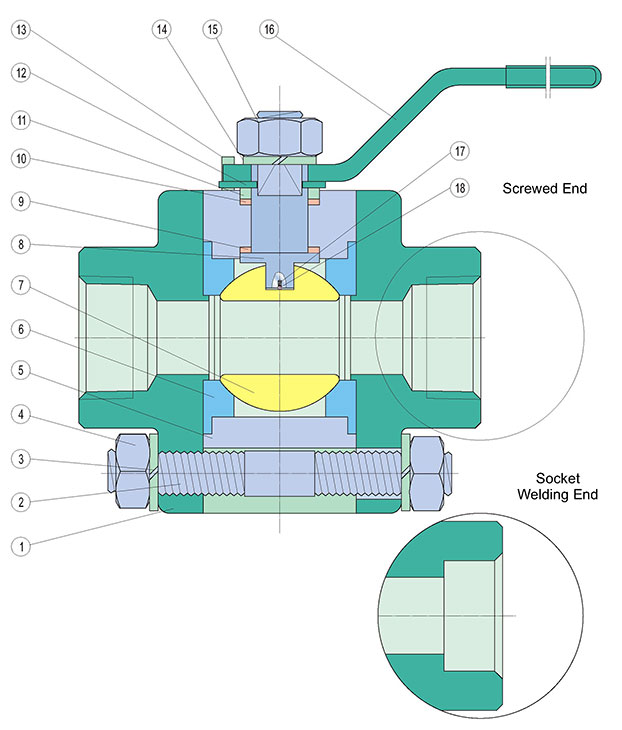

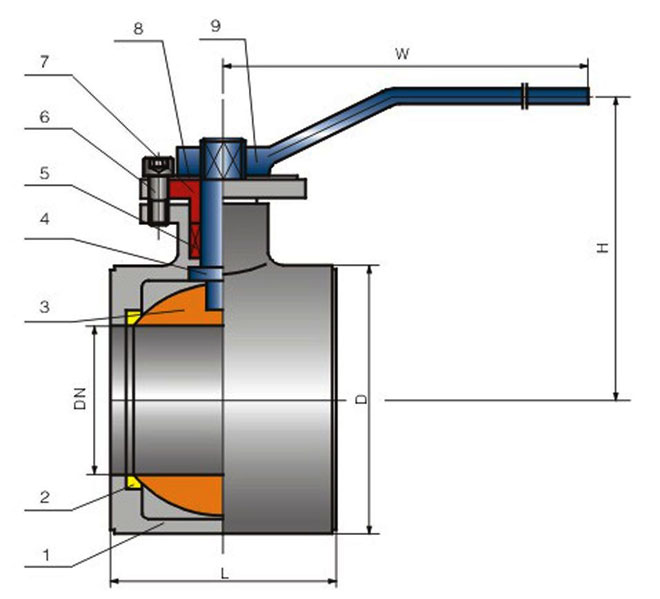

3PCS Body Forge Steel Ball Valve

800LB,1500LB,2500LB

| 3PC Body Forge Steel Floating Ball Valve : NPT, SW, BW | ||

| Features | Specifications | |

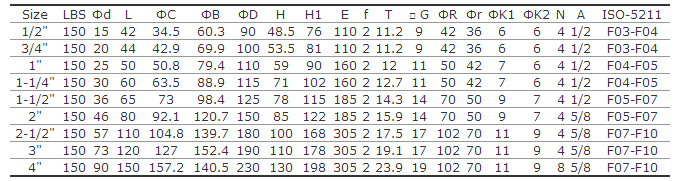

| Size: 1/2″~2″ | Design | ASME 16.34/BS 5351 |

| Class: 800LB,1500LB,2500LB | Face to Face | ASME B16.10 |

| 3 Pieces,Forge Steel Body | End to End | ASME B16.10 |

| Floating Ball, Full & Reduced Bore | NPT | ASME B1.20.1 |

| Anti-Static Device | BW&SW End | ASME B16.25 |

| Blow-out Proof Stem | Test | API 598/ BS 6755 |

| Fire Safe Design | Fire Safe Test | API 607/API 6FA |

| Low Emission | Special | NACE MR-01-7 |

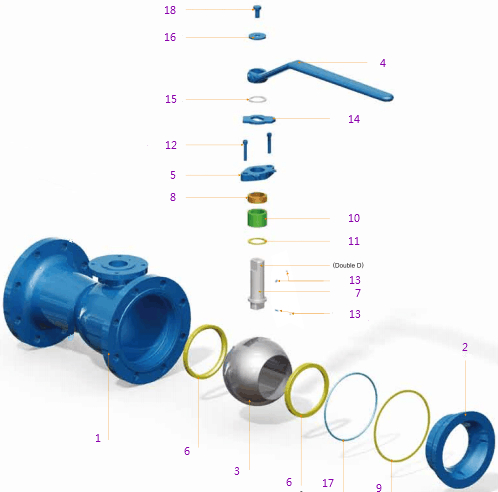

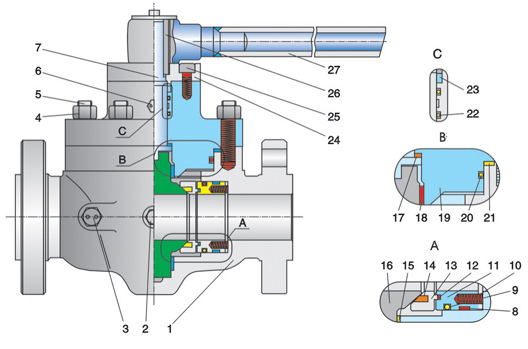

| No. | Part | A105/304 | A105/316 |

| 1 | Adapter | ASTM A105 | ASTM A105 |

| 2 | Body Bolt | ASTM A193-B7 | ASTM A193-B7M |

| 3 | Spring Washer | Carbon Steel | Carbon Steel |

| 4 | Body Nut | ASTM A194-2H | ASTM A194-2HM |

| 5 | Body | ASTM A105 | ASTM A105 |

| 6 | Seat | PTFE | PTFE |

| 7 | Ball | ASTM A182-F304 | ASTM A182-316 |

| 8 | Stem | ASTM A276-304 | ASTM A276-316 |

| 9 | Thrust Washer | PTFE | PTFE |

| 10 | ‘Stem Packing | PTFE | PTFE |

| 11 | Gland | ASTM A276-410 | ASTM A276-410 |

| 12 | Stop Plate | Carbon Steel | Carbon Steel |

| 13 | Stop Pin | Carbon Steel | Carbon Steel |

| 14 | Spring Washer | Carbon Steel | Carbon Steel |

| 15 | Lever Nut | ASTM A194-2H | ASTM A194-2H |

| 16 | Lever | Carbon Steel | Carbon Steel |

| 17 | Antistatic Spring | Stainless Steel | Stainless Steel |

| 18 | Steel ball | Stainless Steel | Stainless Steel |

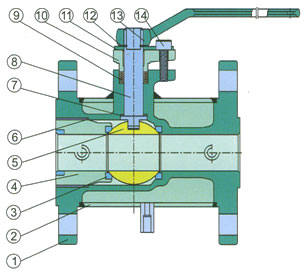

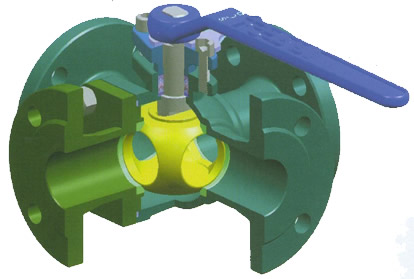

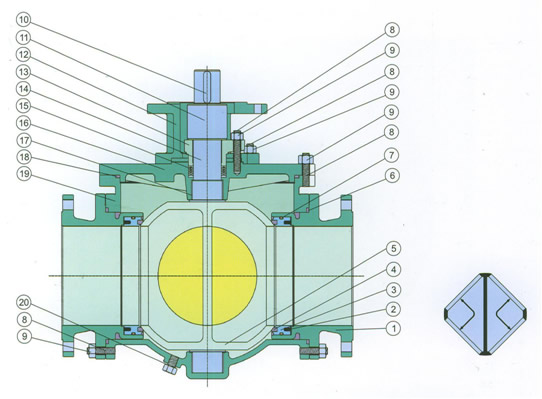

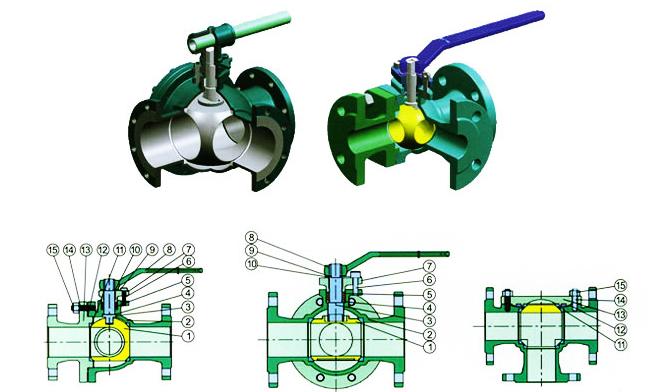

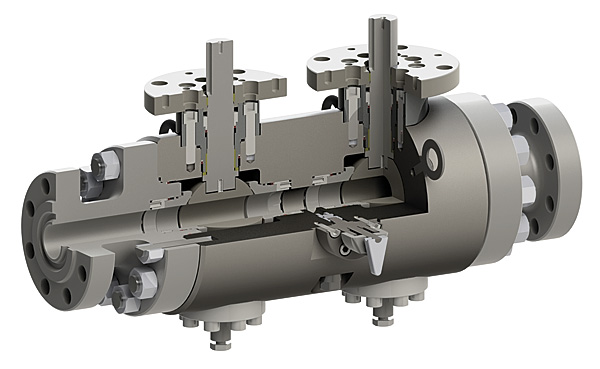

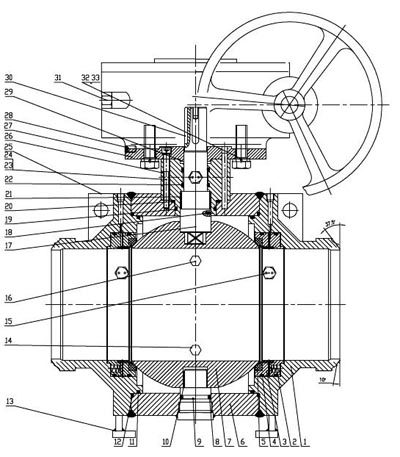

Double Block and Bleed Ball Valves are aimed to get a double barrier on the piping, and bleed the fluid trapped between the two balls from a dedicated drain line. Body construction can be either forging or centrifugal casting. Wide range of materials: carbon steels, austenitic or martensitic SS, duplex-superduplex SS, nickel-based alloys.

Double Block and Bleed Ball Valves are aimed to get a double barrier on the piping, and bleed the fluid trapped between the two balls from a dedicated drain line. Body construction can be either forging or centrifugal casting. Wide range of materials: carbon steels, austenitic or martensitic SS, duplex-superduplex SS, nickel-based alloys.

MAIN FEATURES:

MAIN FEATURES: