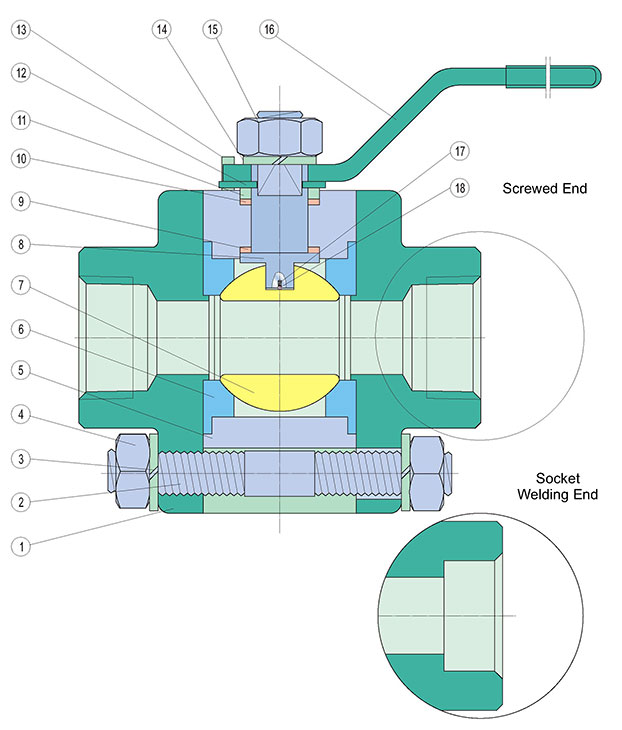

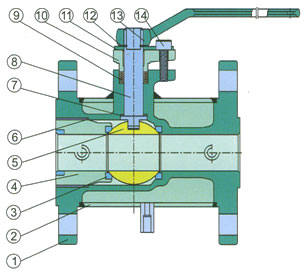

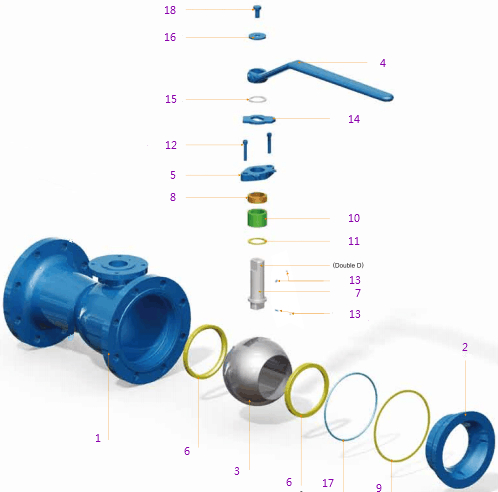

1000 WOG 3PCS Ball Valve

3PCS Body Forge Steel Ball Valve

800LB,1500LB,2500LB

| 3PC Body Forge Steel Floating Ball Valve : NPT, SW, BW | ||

| Features | Specifications | |

| Size: 1/2″~2″ | Design | ASME 16.34/BS 5351 |

| Class: 800LB,1500LB,2500LB | Face to Face | ASME B16.10 |

| 3 Pieces,Forge Steel Body | End to End | ASME B16.10 |

| Floating Ball, Full & Reduced Bore | NPT | ASME B1.20.1 |

| Anti-Static Device | BW&SW End | ASME B16.25 |

| Blow-out Proof Stem | Test | API 598/ BS 6755 |

| Fire Safe Design | Fire Safe Test | API 607/API 6FA |

| Low Emission | Special | NACE MR-01-7 |

| No. | Part | A105/304 | A105/316 |

| 1 | Adapter | ASTM A105 | ASTM A105 |

| 2 | Body Bolt | ASTM A193-B7 | ASTM A193-B7M |

| 3 | Spring Washer | Carbon Steel | Carbon Steel |

| 4 | Body Nut | ASTM A194-2H | ASTM A194-2HM |

| 5 | Body | ASTM A105 | ASTM A105 |

| 6 | Seat | PTFE | PTFE |

| 7 | Ball | ASTM A182-F304 | ASTM A182-316 |

| 8 | Stem | ASTM A276-304 | ASTM A276-316 |

| 9 | Thrust Washer | PTFE | PTFE |

| 10 | ‘Stem Packing | PTFE | PTFE |

| 11 | Gland | ASTM A276-410 | ASTM A276-410 |

| 12 | Stop Plate | Carbon Steel | Carbon Steel |

| 13 | Stop Pin | Carbon Steel | Carbon Steel |

| 14 | Spring Washer | Carbon Steel | Carbon Steel |

| 15 | Lever Nut | ASTM A194-2H | ASTM A194-2H |

| 16 | Lever | Carbon Steel | Carbon Steel |

| 17 | Antistatic Spring | Stainless Steel | Stainless Steel |

| 18 | Steel ball | Stainless Steel | Stainless Steel |

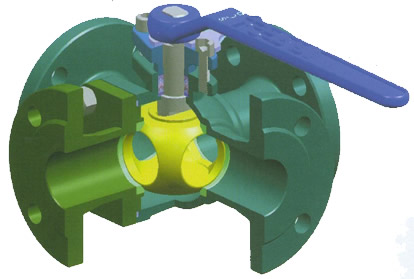

| Three Way Ball Valve | ||

| Features | Specifications | |

| Size: 1/2″~8″ | Design | ASME 16.34/BS 5351 |

| Class: 150~300LB | Face to Face | ASME B16.10 |

| 2 Pieces Cast Steel Body | End to End | ASME B16.10 |

| Float Ball, Full & Reduced Bore | End Flange | ASME B16.5 |

| Anti-Static Device | BW End | ASME B16.25 |

| Blow-out Proof Stem | Test | API 598/ BS 6755 |

| Fire Safe Design | Fire Safe Test | API 607/API 6FA |

| Low Emission | Special | NACE MR-01-7 |

| No. | Part | Material |

| 1 | Body | A216-WCB A352-LCB A351-CF8, CF8M, CF3, CF3M, Duplex |

| 2 | Jacket | 1015 Stainless Steel |

| 3 | Seat | PTFE RTPFE PEEK PPL |

| 4 | Screwed Cover | A216-WCB A352-LCB A351-CF8, CF8M, CF3, CF3M, Duplex |

| 5 | Ball | A351-CF8, CF8M, CF3, CF3M, Duplex |

| 6 | Gasket | PTFE Graphite |

| 7 | Thrust Washer | PTFE |

| 8 | Stem | ASTM A105+ENP A182-F6, F316, F316L, F304L,17-4PH, F51 |

| 9 | Packing | PTFE Graphite |

| 10 | Gland Flange | A216-WCB A351-CF8 |

| 11 | Limited Plate | 1015+Cr. Carbon Steel+Cr. |

| 12 | Retainer | Carbon Steel |

| 13 | Lever | A216-WCB |

| 14 | Screw | ASTM A193-B7, B8 |

| No. | Accessory name | Material |

| ASTM | ||

| 1 | Jacket | A105 |

| 2 | Seat | A216-WCB |

| 3 | Body | A105 |

| 4 | Sealing Ring | PTFE, Counterpoint polyphony |

| 5 | Ball | |

| 6 | Stem | A247-410 |

| 7 | Stuffing | Graphite |

| 8 | Gland | A216-WCB |

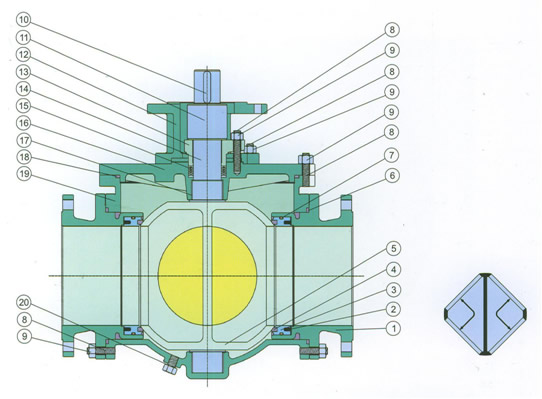

| Features | Specifications | |

| Size: 2″~20″ | Design | ASME 16.34/BS 5351 |

| Class: 150~300LB | Face to Face | ASME B16.10 |

| 2 Pieces or Multi-Pieces Cast Body | End to End | ASME B16.10 |

| Float Ball & Trunnion Mount, Full & Reduced Bore |

End Flange | ASME B16.5 |

| Anti-Static Device | BW End | ASME B16.25 |

| Blow-out Proof Stem | Test | API 598/ BS 6755 |

| Fire Safe Design | Fire Safe Test | API 607/API 6FA |

| Low Emission | Special | NACE MR-01-7 |

| No. | Part | Material |

| 1 | Bonnet | A216-WCB A352-LCB A351-CF8, CF8M, CF3, CF3M, Duplex |

| 2 | Seat Spring | Inconel X-750 S.S.304 S.S.316 |

| 3 | Seat Ring | ASTM A105+ENP A182-F6, F316, F316L, F304 |

| 4 | Seat | PTFE RTPFE PEEK PPL |

| 5 | Ball | A351-CF8, CF8M, CF3, CF3M, Duplex |

| 6 | Gasket | PTFE S.S.304+Graphite S.S.316+Graphite |

| 7 | O-ring | NBR Viton |

| 8 | Stud | ASTM A193-B7, B7M, B8, B8M |

| 9 | Nut | ASTM A194-2H, 2HM, 8, 8M |

| 10 | Key | 1045 Stainless Steel |

| 11 | Coupling | ASTM A105+ENP A182-F6 |

| 12 | Yoke | A216-WCB A351-CF8 |

| 13 | Gland Flange | A216-WCB A351-CF8, CF8M |

| 14 | Stem | ASTM A105+ENP A182-F6, F316, F316L, F304L,17-4PH, F51 |

| 15 | Packing | PTFE Graphite |

| 16 | Cover | A216-WCB A352-LCB A351-CF8, CF8M, CF3, CF3M, Duplex |

| 17 | Sliding Bearing | Stainless Steel + PTFE S.S.316+PTFE |

| 18 | Gasket | PTFE S.S.304+Graphite S.S.316+Graphite |

| 19 | Body | A216-WCB A352-LCB A351-CF8, CF8M, CF3, CF3M, Duplex |

| 20 | Vent Valve | Carbon Steel+ENP A182-F304, F316, F316L ,F304L |

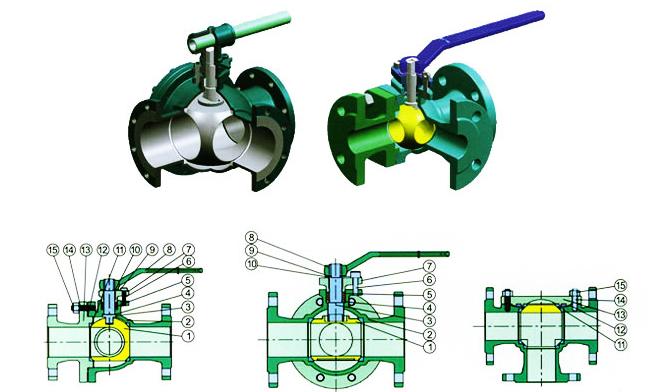

Three Way Ball Valve 150LB/300LB

| Three Way Ball Valve | ||

| Features | Specifications | |

| Size: 1/2″~8″ | Design | ASME 16.34/BS 5351 |

| Class: 150~300LB | Face to Face | ASME B16.10 |

| 2 Pieces Cast Steel Steel Body | End to End | ASME B16.10 |

| Float Ball, Full & Reduced Bore | End Flange | ASME B16.5 |

| Anti-Static Device | BW End | ASME B16.25 |

| Blow-out Proof Stem | Test | API 598/ BS 6755 |

| Fire Safe Design | Fire Safe Test | API 607/API 6FA |

| Low Emission | Special | NACE MR-01-7 |

| No. | Part | Material |

| 1 | Ball | A351-CF8, CF8M, CF3, CF3M, Duplex |

| 2 | Body | A216-WCB A352-LCB A351-CF8, CF8M, CF3, CF3M, Duplex |

| 3 | Stem | ASTM A105+ENP A182-F6, F316, F316L, F304L,17-4PH, F51 |

| 4 | Thrust Washer | PTFE |

| 5 | Packing | PTFE Graphite |

| 6 | Screw | ASTM A193-B7, B8 |

| 7 | Gland Flange | A216-WCB A351-CF8 |

| 8 | Lever | A216-WCB |

| 9 | Limited Plate | 1015+Cr. Carbon Steel+Cr. |

| 10 | Retainer | Carbon Steel |

| 11 | Seat | PTFE RTPFE PEEK PPL |

| 12 | Gasket | Stainless Steel+Graphite S.S.316+Graphite |

| 13 | Bonnet | A216-WCB A352-LCB A351-CF8, CF8M, CF3, CF3M, Duplex |

| 14 | Stud | ASTM A193-B7, B7M, B8, B8M |

| 15 | Nut | ASTM A194-2H, 2HM, 8, 8M |

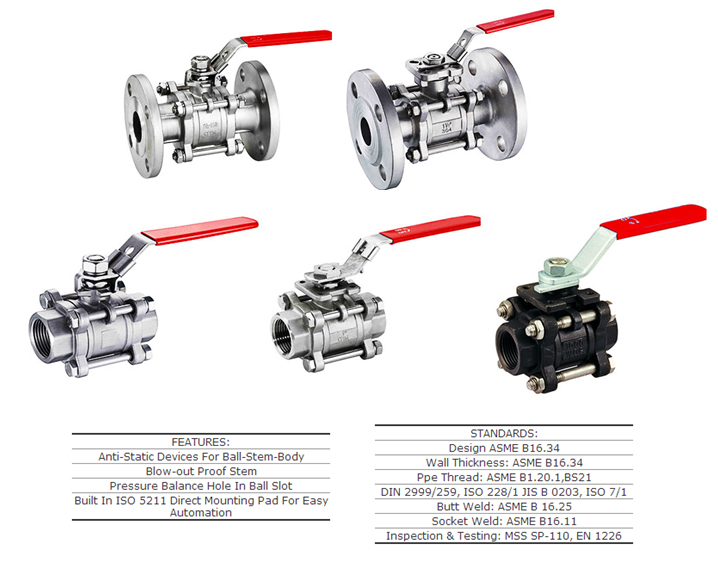

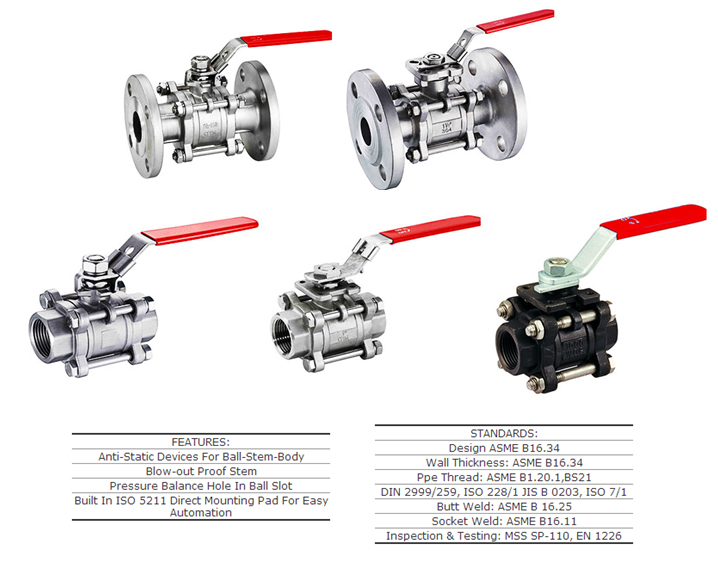

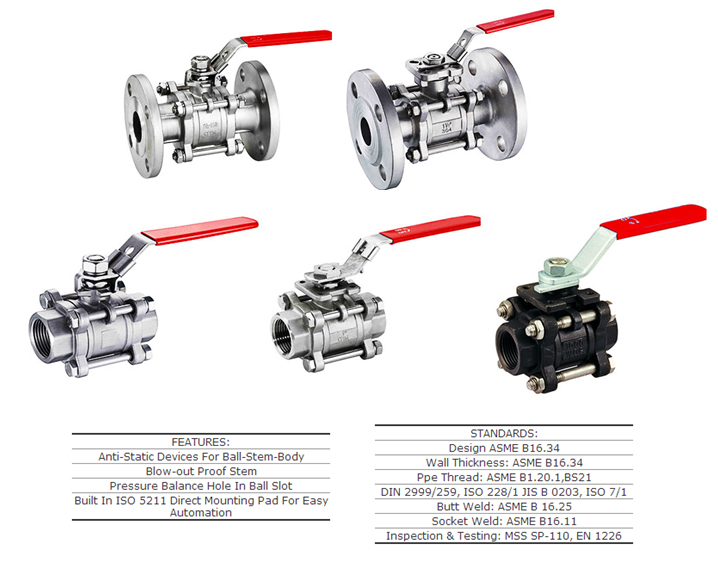

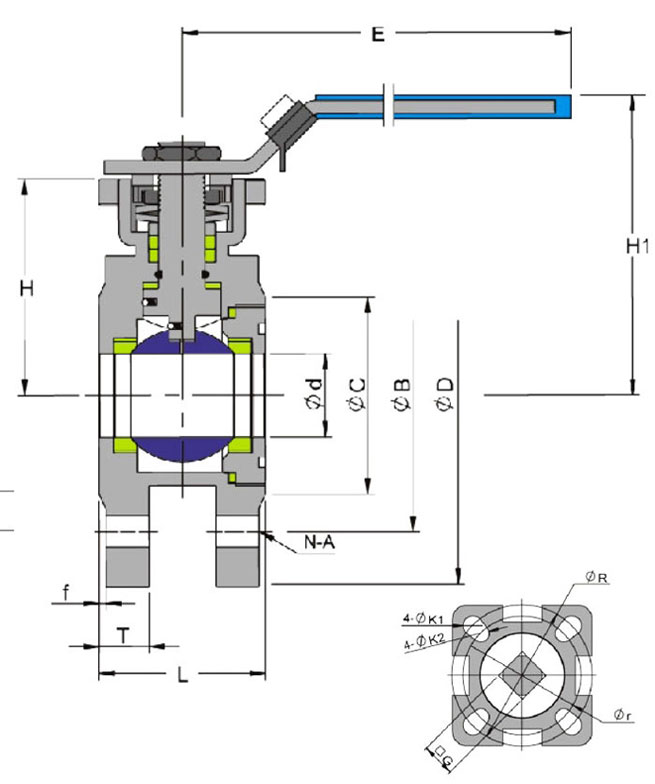

| FEATURES: |

| Anti-Static Devices For Ball-Stem-Body |

| Blow-out Proof Stem |

| Pressure Balance Hole In Ball Slot |

| Built In ISO 5211 Direct Mounting Pad For Easy Automation |

| STANDARDS: |

| Design: ASME B16.34 |

| Wall Thickness: ASME B16.34 |

| Fire Safe: API 607 ISO 10497 |

| End Flange: ASME B16.5 |

| Inspection & Testing: API 598 |

FORGE STEEL WAFER BALL VALVE 150LB/300LB

| No. | Parts Name | Material | |

| Stainless Steel | Cast Steel | ||

| 1 | Body | CF8 | WCB |

| 2 | Seat | PTFE/PPL | PTFE/PPL |

| 3 | Ball | 304 | 304 |

| 4 | Stem | 304 | 2Cr13 |

| 5 | Packing | PTFE | Graphite |

| 6 | Gland | CF8 | WCB |

| 7 | Handle | WCB | WCB |

| NPS (in) |

DN (mm) |

Dimension (mm) | ||||||||

| L | D | L0 (Manual operated) |

H | WT(Kg) | ||||||

| Manual | Pneumatic | Electric | Manual | Pneumatic | Electric | |||||

| 1/2 | 15 | 40 | 53 | 140 | 80 | 225 | 320 | 0.9 | 4.2 | 7.8 |

| 3/4 | 20 | 45 | 63 | 180 | 80 | 228 | 320 | 1.3 | 4.5 | 8.1 |

| 1 | 25 | 50 | 73 | 180 | 100 | 233 | 340 | 1.6 | 5.8 | 8.6 |

| 11/4 | 32 | 60 | 84 | 200 | 110 | 259 | 350 | 2.6 | 8.9 | 9.5 |

| 11/2 | 40 | 70 | 94 | 200 | 120 | 267 | 360 | 3.8 | 10.2 | 11 |

| 2 | 50 | 80 | 109 | 250 | 130 | 278 | 370 | 5 | 11.5 | 12 |

| 21/2 | 65 | 110 | 129 | 300 | 140 | 363 | 380 | 7.5 | 26.5 | 14.5 |

| 3 | 80 | 120 | 144 | 350 | 150 | 383 | 450 | 11 | 30 | 45 |

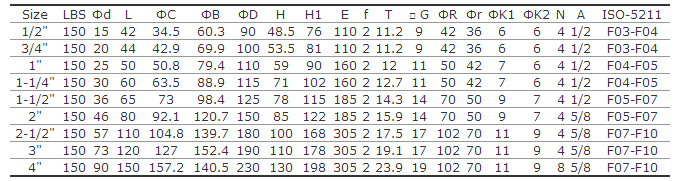

| No | Part | Standard | Stainless Steel | SourService | Low Temp. Service |

|---|---|---|---|---|---|

| 1 | Body | ASTM A216-WCB | ASTM A351-CF8M | ASTM A216-WCB | ASTM A352-LCB |

| 2 | Bonnet | ASTM A216-WCB | ASTM A351-CF8M | ASTM A216-WCB | ASTM A352-LCB |

| 3 | Ball | ASTM A105N/ENP | ASTM A182-F316 | ASTM A105N/ENP | ASTM A182-F316 |

| 4 | Lever | Carbon Steel | Carbon Steel | Carbon Steel | Carbon Steel |

| 5 | Gland Flange | ASTM A216-WCB | ASTM A351-CF8 | ASTM A216-WCB | ASTM A352-LCB |

| 6 | Seating Ring | PTFE | PTFE | PTFE | PTFE |

| 7 | Stem | ASTM A182-F6a | ASTM A182-F316 | ASTM A182-F6a | ASTM A182-F316 |

| 8 | Gland | ASTM A276-420 | ASTM A276-316 | ASTM A276-420 | ASTM A276-316 |

| 9 | Gasket | 316 S.S.+Graphite | 316 S.S.+Graphite | 316 S.S.+Graphite | 316 S.S.+Graphite |

| 10 | Packing Set | Graphite | Graphite | Graphite | Graphite |

| No | Part | Standard | Stainless Steel | SourService | Low Temp. Service |

|---|---|---|---|---|---|

| 11 | Thrust Washer | PTFE | PTFE | PTFE | PTFE |

| 12 | Bolt | ASTM A193-B7 | ASTM A193-B8 | ASTM A193-B7M | ASTM A320-L7M |

| 13 | Anti-Static Device | S.S. | S.S. | S.S. | S.S. |

| 14 | Stop Plate | Carbon Steel | Carbon Steel | Carbon Steel | Carbon Steel |

| 15 | Retainer | Carbon Steel | S.S. | Carbon Steel | S.S. |

| 16 | Washer | Carbon Steel | S.S. | Carbon Steel | S.S. |

| 17 | O-Ring | Viton A | Viton A | Viton A | HNBR |

| 18 | Bolt | Carbon Steel | S.S. | Carbon Steel | S.S. |

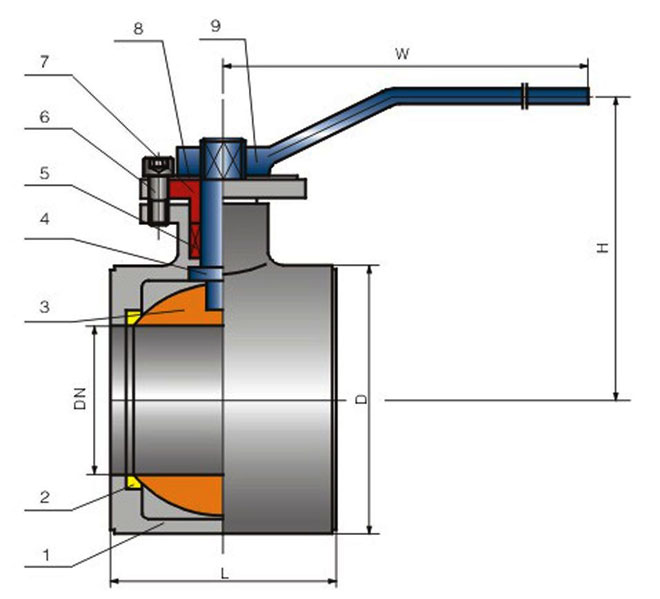

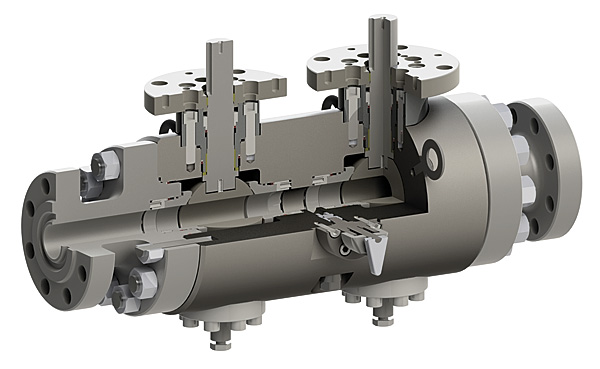

Double Block and Bleed Ball Valves are aimed to get a double barrier on the piping, and bleed the fluid trapped between the two balls from a dedicated drain line. Body construction can be either forging or centrifugal casting. Wide range of materials: carbon steels, austenitic or martensitic SS, duplex-superduplex SS, nickel-based alloys.

Double Block and Bleed Ball Valves are aimed to get a double barrier on the piping, and bleed the fluid trapped between the two balls from a dedicated drain line. Body construction can be either forging or centrifugal casting. Wide range of materials: carbon steels, austenitic or martensitic SS, duplex-superduplex SS, nickel-based alloys.

Valve design can be either Trunnion or Floating type, anti blow-out stem and typically SPE seat design. Drain port is normally provided with a floating ball valve, to be fitted with Final User drain line. Valve seats can be soft or metal to metal hard-faced.

Main reference codes:

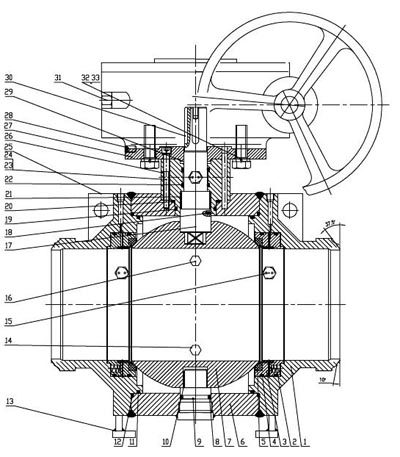

Full Welded Trunnion Mounted Ball Valve

150Lb/300Lb/600Lb/900Lb/1500Lb

| FEATURES | SPECIFICATIONS | |

| Size: 2″~60″ | Design | ASME B16.34/API 6D |

| Class: 150~1500Lb | Face to Face | ASME B16.10 |

| Three Pieces Forged Steel Body | End Flange | ASME B16.5 |

| Trunnion Mounted Ball, Full Bore | BW End | ASME B16.25 |

| Anti-static Device | Test | API 598/API 6D |

| Blow-out Proof Stem | Fire Safe Test | API 607/API 6FA |

| Fire Safe Design | Special | NACE MR-01-75 |

| Emergency Sealant Injector | Application | Chemical processing |

| Oil Field & Power Plant | ||

| Hydrocarbon processing | ||

| Vent Valve, Drain Valve | ||

| Lifting Lugs and supporting feets | ||

| STANDARD MATERIAL LIST | ||

| No. | Parts Name | Material |

| 1 | Bonnet | A105+ENP, A182 F6, F304, F304L, F316, F316L, F51 |

| 2 | Spring | Inconel X-7505, SS304, SS316 |

| 3 | Seat | A105+ENP, A182 F6, F304, F304L, F316, F316L, F51 |

| 4 | O-ring | PTFE |

| 5 | Seat Ring | R-PTFE, PEEK, PPL , DEVLON |

| 6 | Body | A105+ENP, A182 F6, F304, F304L, F316, F316L, F51 |

| 7 | Ball | A105+ENP, A182 F6, F304, F304L, F316, F316L, F51 |

| 8 | O-ring | Viton |

| 9 | Trunnion | A105+ENP, A182 F6, F304, F304L, F316, F316L, F51 |

| 10 | Sliding Bearing | SS304+PTFE |

| 11 | O-ring | Viton |

| 12 | O-ring | Viton |

| 13 | Support | Q235-A |

| 14 | Drain Valve | 1020+ZN, A182 F304, F304L, F316, F316L |

| 15 | Grese Valve | 1020+ZN, A182 F304, F304L, F316, F316L |

| 16 | Vent | 1020+ZN, A182 F304, F304L, F316, F316L |

| 17 | Stem | A105+ENP, A182 F6, F304, F304L, F316, F316L, F51 |

| 18 | Anti-static Spring | Stainless Steel |

| 19 | O-ring | Viton |

| 20 | Gland Gasket | SS304+Graphite |

| 21 | Sliding Bearing | SS304+PTFE, SS316+PTFE |

| 22 | O-ring | Viton |

| 23 | Bolt | A193 B7, B7M, B8, B8M |

| 24 | Gasket | SS304+Graphite |

| 25 | Lifting Lug | Q235-A |

| 26 | Bonnet | A105+ENP, A182 F6, F304, F304L, F316, F316L, F51 |

| 27 | Top Flange | A105+ENP, A182 F6, F304, F304L, F316, F316L, F51 |

| 28 | Stud | A193 B7, B7M, B8, B8M |

| 29 | Packing | Graphite |

| 30 | Key | 1045, A182 F304, F304L, F316, F316L |

| 31 | Worm Gear | Duction Iron |

| 32 | Bolt | A193 B7, B7M, B8, B8M |

| 33 | Gasket | SS304+Graphite |

| Performance Specification |

| Performance Specification | Class | |||||||

| 150 | 300 | 400 | 600 | 900 | 1500 | 2500 | ||

| Test Pressure(MPa) | Strength Test | 2.93 | 7.58 | 10.0 | 15.0 | 22.5 | 37.5 | 63.0 |

| Sealing Test | 2.07 | 5.52 | 7.31 | 11.03 | 16.5 | 27.5 | 46.2 | |

| Pressure Test | 0.6 | |||||||

| Applicable Temperature | -196?~550? Different Raw Material for Different Work Temperature | |||||||

| Applicable Medium | Water,Steam,Oil,Gas,Petrochemical and other comparable | |||||||

| Size Range | DN50~1200(NP2?~48?),DN50~1200(NP2?~48?),We can produce valve according to your special requirments. | |||||||

| Body/Trim Material | Carbon Steel,SS,Ni-Alloy Steel,Ti Material | |||||||

| Bottom Connection | Flange Connection,Butt Welded Connection | |||||||

| Operation set | Hand Wheel Operation,Worm Gear Operation,Electric Operation,Pneumatic Operation | |||||||

| The Material of Main Parts |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

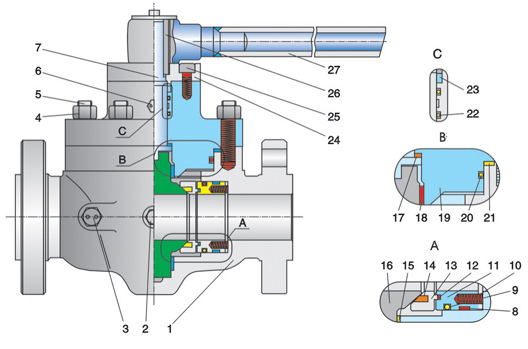

MAIN FEATURES:

MAIN FEATURES:

The seat material of general purpose ball valve employs generally non-material,such as PTFE.Limited by the seat material ,the general purpose ball valve can not be used in case of high articles,and ash dregs neither.

Metal to metal seat design has been employed perfectly for the ball and seat,which has also adopted the advanced hardening technologies,such as ultro-sonic spray coating,nickel base spay welding,surface specially hardening,stellite spay welding,ceramic material with high strength and hardness,and so on.Surface hardness of ball and seat may generally reach more than HRC60, maximun is up to HRC74.

And application temperature of the material may be to 540℃,maximun is 980℃.Combining strength of the material gets to be more than 10000 PSI.Besides,the surface materials posses also very good resistance properties of friction and impact.

Nipo metal to metal seat ball valves are suitable for use in most hard working conditions.

Main Parameter Specification

Design and Manufacture:API 6D,ASME B16.34(BS5351),API 608,MSS-SP-72

Face to Face Dimension:ASME B16.10,API 6D

Flange Connection Dimension:ASME B 16.5

BW Connection Dimension:ASME B16.25

Test and Inspection:API 598,API 6D

Fire-Safe Design:API 607/6FA

Anti-Static Design&Anti Blow-Out Stem

Product Range

Body material: carbon steel, stainless steel, alloy steel

Full bore and reduced bore design

Nominal diameter:1/2″~48″(DN15~DN1200)

End Connection: RF,RTJ, BW

Pressure range: Class150~2500(PN16~PN420)

Working temperature: -46℃~+540℃

Operation : Handle, Gear, Electric actuator, etc